Introduction

Introduction

Smith’s are a UK based manufacturer with over 30 years experience of working with companies to provide a fast, flexible and reliable contract manufacturing service to many different types of customers. From one-off fully bespoke products to contract manufacturing of components such as heat exchangers or fabrication of products. Smith’s has both the expertise and experience to provide this service.

Being UK based there are no potential problems with currency fluctuations.

For all enquiries please email info@smithsep.co.uk

Design capabilities

Design capabilities

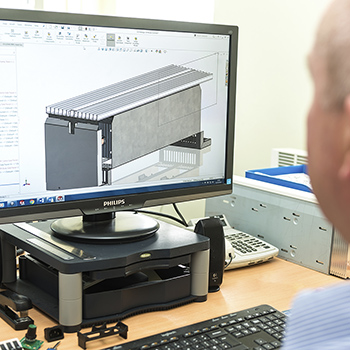

Using the latest version of Solidworks design and modelling software our highly experienced and technical people can design and develop 3D models.

Our R&D team are very familiar with designing to UL Standards. Since 1991 we have been selling UL compliant solutions to the USA.

Factory Facilities

Factory Facilities

Operating from 40,000 square feet of factory and office space near Chelmsford in Essex we manufacture our product range from raw materials through to finished product using computerised design and automated production techniques. We are happy to welcome customers to visit our factory and Head Office to demonstrate our capabilities.

In the last 2 years we have implemented some key initiatives to improve productivity and to ensure the quality continues to meet the highest standards.

Lean initiatives such as Kaizen, or continuous improvement process, have brought significant improvements in the factory. On-going initiatives such as the implementation of the gemba walk continue drive innovation and to maximize the improvement process.

We also employ well-regarded 8D and six-sigma techniques to ensure product quality is achieved.

Manufacturing Capabilities

Manufacturing Capabilities

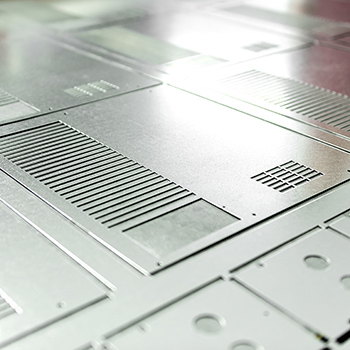

We perform all fabrication in-house using our modern CNC machines and welding capabilities. We have capabilities in punching, bending, welding, brazing and heat exchanger manufacture. We also have a high quality 2 booth paint shop.

In terms of the capabilities of Smith’s we have the following equipment in the Fabrication Facility:

- Amada Punching Machines

- TiG welding capability

- Manual Fly Press

- Amada Bending machines

Coil Block Production

- Spot Welding capability, Linishing, Coil expanding and Fin Presses.

Brazing

- In the brazing section there are several Brazing Stations, with Pillar drills, pipe bending equipment band saws and lathes.

Paint Shop

- We have 2 spray booths capable of handing any RAL colour, a Treble Oven, Degreaser tank and a Strapping machine

Assembly Area

- There are several electrical testing stations linked to a main server for data recording and a Strapping machine

Quality and the environment

Quality and the environment

At Smith’s we recognise that quality is about more than just the product, it’s an approach that runs throughout the business and is centred on meeting and exceeding customers’ expectations. Processes are constantly monitored and evaluated with a focus on continuous improvement. Manufacturing facilities are regularly appraised and meet the exacting standards of national approval boards such as UL, CSA and Kema.

In 2017 Smith’s was assessed for the highly regarded ISO 9001 (2015) accreditation and passed the audit with no non-conformities and was accredited the new standard certification. It brings Smith’s up to the latest standard and assuring our customers receive the best experience possible.

In 2018 Smith’s was awarded the prestigious ISO 14001 accreditation. ISO 14001 is concerned with setting an environmental framework for the company to work within. This means that Smith’s has management processes and systems to ensure that they manufacture products that meet the customer and regulatory requirements and are working within designated environmental parameters.

Both ISO 9001 (2015) and ISO 14001 accreditations are internationally recognised and demonstrate that Smith’s is a responsible and forward thinking organisation committed to achieving and maintaining the highest organisational standards.

Types of solutions

From specific components to fit inside a product to complete OEM products for sale as Client brand

Expertise in Heating, and cooling products

Heat exchangers

Steel casing

Complete products

Data Centres

Smith’s provide bespoke heating products for Data Centres to enable commissioning testing of the critical air conditioning facilities used to maintain temperature and humidity in Data Centres.

Recently Smith’s have developed a product specifically designed to a customers requirements to provide cooling for a data centre. This product was designed in conjunction with the customer to ensure it accurately met their stringent requirements.

Transport

We manufacture bespoke heating products for transport applications such as trains, trams, where design and develop products to customers’ specifications, using our expertise and knowledge of heat exchangers and controls.

Leisure vehicle applications

Working with several leisure vehicle manufacturers Smith’s design and develop electric heating products for caravans, motorhomes and other leisure vehicles.